When it comes to maintaining engine health, the importance of an efficient and reliable oil filter cannot be overstated. It's imperative that your car's engine receives clean oil to ensure longevity and optimal performance. A crucial piece of this puzzle is the oil filter, designed to capture contaminants before they can cause significant damage.

Contaminants in engine oil such as dirt, metal shavings, and other debris can lead to increased friction and wear on engine components. Without proper filtration, these particles can compromise the lubrication quality of the oil, leading to reduced engine efficiency and potentially costly repairs. The role of oil filters is vital in preventing engine wear by trapping these harmful contaminants.

Anatomy of an Oil Filter

Understanding how an oil filter works starts with its basic structure and components. Key parts include:

- Filter media: This is the primary substance within the filter responsible for capturing contaminants. It can be made from various materials including cellulose, synthetic fibers, or a blend of both.

- Anti-drain back valve: Located in most modern oil filters, this valve prevents oil from draining out of the filter when the engine is turned off, ensuring consistent oil pressure upon startup.

- Relief valve: Also known as a bypass valve, it allows unfiltered oil to circulate if the filter becomes clogged, preventing oil starvation in the engine.

- End disc: These seal the ends of the cylindrical filter element to maintain structural integrity and prevent leaks.

There are several types of oil filters available, each serving different purposes:

- Full-flow filters: Designed to filter all the engine oil at once, ensuring constant protection against contaminants.

- Bypass filters: Operate parallel to full-flow filters and provide finer filtration but only filter a small portion of the oil flow at any given moment.

- Cartridge filters: An older design where the filtering element is replaced while the outer casing is reused.

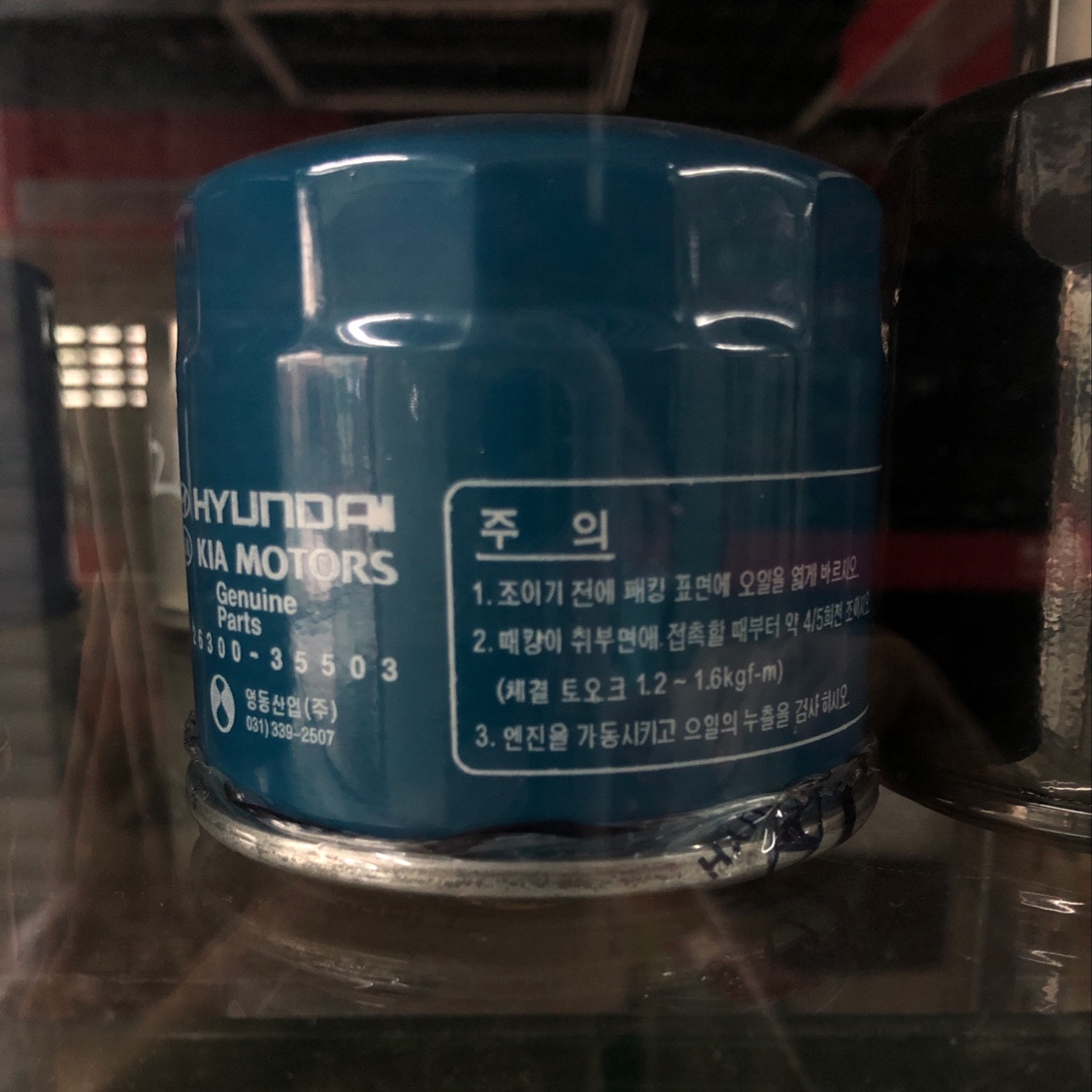

- Spin-on filters: Modern filters featuring a sealed body, making them easier to replace without mess.

Filtration Mechanisms

The process of filtering oil involves allowing it to pass through the filter medium where contaminants are trapped through a combination of mechanical and chemical processes. There are two main types of filtration mechanisms:

- Surface filtration: Captures particles on the surface of the filter media, suitable for larger particles.

- Depth filtration: Involves trapping particles within the layers of the filter media, effective for capturing smaller contaminants.

Synthetic and cellulose media play a pivotal role in enhancing filtration efficiency and capacity. Synthetic blends often offer better performance due to their ability to trap more contaminants without causing a significant drop in oil flow rate.

Performance Metrics

When evaluating the performance of an oil filter, several key metrics should be considered:

- Filtration efficiency: Typically represented by micron ratings, which indicate the smallest size particle the filter can capture effectively.

- Filter capacity: Refers to the amount of contaminants the filter can hold before becoming clogged.

- Flow rates and pressure drops: Balancing filtration efficiency with adequate oil flow is essential to avoid restricting oil circulation, which could harm engine performance.

Advances in Oil Filter Technology

Recent innovations have led to significant advancements in oil filter technology, including the development of synthetic blends and nano-fiber technology which enhance the durability and effectiveness of filters. Additionally, smart oil filters equipped with sensors enable real-time monitoring of the oil condition, providing critical data for timely replacements. Eco-friendly designs, like reusable and biodegradable options, are also gaining popularity due to their environmental benefits.

Maintenance Tips

Proper maintenance of your car’s oil filter is fundamental to preserving engine health. Watch for signs of a failing oil filter, such as decreased engine performance or unusual noises. Regular replacement intervals, typically between 3,000 to 7,500 miles depending on driving conditions and manufacturer recommendations, should be adhered to. Selecting the right oil filter for your specific vehicle type ensures compatibility and efficiency.

Common Myths and Misconceptions

Several myths surrounding oil filters persist, such as the notion that all oil filters perform the same or that lifespan claims are universal. Off-brand filters may not meet the stringent standards set by OEM (Original Equipment Manufacturer) filters, potentially impacting your engine's performance and longevity. It's crucial to debunk these misconceptions and prioritize quality over mere convenience or cost-saving measures.

Real-World Applications

Poor oil filtration can lead to significant engine issues, as illustrated by numerous case studies highlighting diminished engine performance and heightened repair costs. Testimonials from mechanics and enthusiastic car owners further underline the significance of utilizing high-quality oil filters to ensure engine robustness and reliability.

Future Directions in Oil Filtration

The landscape of automotive filtration technologies continues to evolve with emerging trends focusing on higher efficiency and adaptability to new engine types, such as those found in hybrid and electric vehicles. As these technologies advance, oil filters will remain a cornerstone in sustaining engine health across various vehicle platforms.

In conclusion, understanding the inner workings of car oil filters affirms their vital role in engine maintenance. From the basic anatomy and filtration mechanisms to ongoing technological advances and common misconceptions, it's clear that investing in quality oil filters and adhering to regular maintenance schedules are key to ensuring your engine's longevity and optimal performance. Choosing products like the Lisheng Car Oil Filter guarantees reliability and durability, safeguarding your vehicle’s most critical components.